Engine In

17th August 2011

I picked up the replacement rings a few days later, and recieved my ring expander tool in the post. It only took a couple of nights to put everything back together. Suffice to say that the ring expander is well worth the small investment. From my position of experience, I can say without doubt that it's stupid not to buy one.

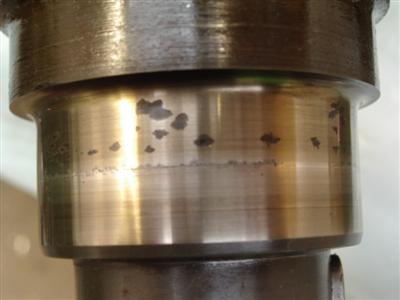

I did find a slightly bad thing, in the shape of the front oil seal. This has been rather badly damaged, and worse, seems to have scratched the crank slightly as well. Obviously this happened when the engine was being turned over during the balancing:

Now thinking back, I do remember this one seeming very tight. So maybe it wasn't quite the right size? It could be just that it ran dry and started to rub, but they'd sprayed plenty of oil in at the balancers, so that seems unlikley - and the front seal is perfect. So I'm guessing that it was a wrong 'un. I'll try to get one from an Alfa dealer to be sure. Whichever, I'd rather it goes now than when it's running for real. Hopefully the scoring on the crank shouldn't matter too much, it's very slight and it's only a sealing surface, not a bearing one.

Anyway, I figured that I could do that when it's in the car as easy as when it's on the bench, so it was on with the fitting. I fitted the flywheel, clutch, and gearbox during the week, ready for the big fitting day at the weekend. This time, I didn't fit the sump or the oil pump pickup. This is because I am now convinced that I'm going to have to get a shallower sump made up, so there's no point sealing it all on; and also, because not having it on gives a good few inches more clearance to get the thing into the engine bay.

Come the day, I had a streaming cold, which was nice, but I wanted to get on with it. I stripped the car down, removing sides, bonnet, scuttle, and tunnel. I stacked all the bits in the kitchen as they take up rather a lot of room! Hopefully, this will be the last time I see the car in such a naked state - or at least, the last time for long time. This took just over an hour, then another two to actually get the engine in and seated. Would have been quicker with help, but I was on my own since the missus was at work.

Engine going in...extreme angle required to start with!

Engine going in...extreme angle required to start with!

Tightening everything up properly, then carting everything back out of the kitchen and putting it back on the car (mostly with just a couple of bolts for now) took another couple of hours, by which time I was pretty tired. But I squeezed in another hour to put the cylinder heads on - mainly to keep everything clean inside, but also because it cleared up some floor space. At this stage, I haven't torqued them up, just sat them in place really. I want to check that there is enough clearance between the valves and pistons before I tighten everything up. I gave the cams a good coating of assembly lube, then noticed two things. The first is that the rocker cover gaskets and bolts were missing. They must have gone AWOL while sitting in the engine builder's shop for a year, which is a little annoying. Secondly, the rocker cover bolts are a funny size - must be M7 I think, it's the same pitch as a 6 but larger. So I'll need to order both. For now though, the covers can just sit on to keep the dust off.

I also couldn't resist plonking the plenum in place and checking if the throttle would now fit with my rearwards pull mechanism. And it looks as if it will, if I chop a bit off the clutch pedal (arrowed)

So I might not need the extension I made up ages ago, after all. Which would suit me fine.

By this time I was really tired, so I called it a night.

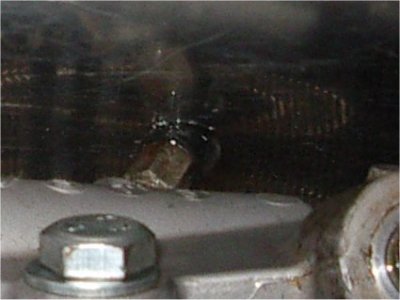

Ooops...

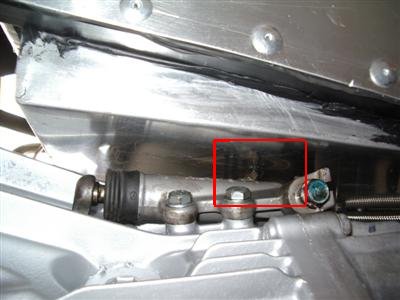

The next time I came to the car, I was checking out the access to the gearbox oil fill plug, as I still need to fill it up. It was then that I noticed a slight clearance "issue" between the slave cylinder and the passenger footwell panel:

That's the bleed nipple rubbing against the footwell. At the time I built the footwell panels, I didn't have the clutch cylinder, so I guessed. Looks like I'll need to make a hole in the footwell, and make up a bulged cover for it. No biggy, and will make it easy to get at the nipple for bleeding. Probably better this way, it would be really awkward to access from underneath, even if I'd made the footwells an inch smaller. Just another unexpected job to do...