Rolling Road

22nd October 2013

So the fateful day came. With assistance from my very helpful neighbour and fellow kit builder, who'd lent me the trailer, we got loaded up on monday night. Rather tricky getting the car onto the trailer in the rain, as it all slid sideways as soon as the back wheels touched the wet metal ramps. A few lengths of timber and a brave "leap of faith" onto the trailer sorted that out. I was also picking up an engine for him en route, he's got this crazy idea about putting a v6 engine into his locost...

The drive down to Nofolk was unneventful, if wet. Towing turned out to be not nearly as bad as I'd feared. The Missus helped with the driving, having more towing experience than me, so the journey wasn't too bad. Got there at 11:30, mopped the half inch of water out of the car, covered it and hit the sack.

The next morning, drove to a petrol station on the way to Emerald (which was only 10 minutes from where we'd stayed) to fill the car up. I also wanted to callibrate the fuel gauge but it wasn't playing. God knows what's up there, I hope I haven't buggered them all up. Anyway, on to Emerald. John was my mapper for the day, and helped me off the trailer and into the garage, after a chat and look around the car. "How long does it normally take?" I asked. "Well, it usually depends on how many bits drop off!" he replied. Great!

Setting up the cell took about a half hour, strapping the car down, sorting out ducting for the exhaust fumes etc.

Left - waiting outside of the test cell. Right - on the rollers, bonnet off, before the room is set up

Left - waiting outside of the test cell. Right - on the rollers, bonnet off, before the room is set up

Then, off we went. An interesting process to watch - he got the idle set correctly in a couple of minutes (I had the warm idle pretty good, but for cold I had the IACV valve open waaaaay too far, and hence was chucking loads of fuel in to compensate - which is why it was so noisy). He got it settled down to 8-9 hundred rpm which sounded loads better. Then begun working up from low load/low rpm, gradually increasing both and filling in the map. As each section was filled in you could hear it respond a little better, run a bit smoother, and generally feel like it was comming to life.

The mapper doing his stuff

The mapper doing his stuff

By the time it was half way through, up to around 4000 rpm at one extreme, and high load / low rpm at the other (an indicated 25mph in 6th on full throttle), it was all looking good. A small oil leak from each rocker cover, still (aaaagh!) but nothing to worry about. The oil pressure gauge magically came to life, it didn't overheat, nothing had dropped off, and it was getting very hot in there. He gave the thing a couple of blips and it sounded vicious, and I thought to myself, "Bloody HELL". Not even up to where it starts properly comming on song yet!

It wasn't to get there of course. A sudden misfire caused him to shut it down, and on restarting, there was a lot of smoke, then raw petrol comming out of the left hand exhaust. Urp. "Probably an injector problem" he said, so I set about removing them. The passenger side ones are easy, the driver's side not so as they are under the intake pipes, so the plenum needs taking off. The injectors went on the test machine; one was stuck open (that'll explain it then), the rest all flowed very closely to 360cc/min, though one had a bit of a bad pattern. There also seemed to be a lot of rubbish in them, not sure where from since all the pipes and tank and everything are new.

Anyway, they had some time in the ultrasonic bath, which seemed to fix things, so I replaced them and away we went again. Unfortunately, after 5 minutes or so, it happened again, so that was that. I'd have bought new injectors there and then, but unfortunately the ones they sell are a different plug (EV14 body style with the oval plug), so there was nothing I could do except pack up and go home, via picking up the engine from a farm in the middle of nowhere.

Got home at around 11, then had to unload the engine, the car, push it up the drive and into the garage, fortunately the neighbour helped otherwise I don't think we'd have managed. Disheartening in some ways, but there were some positives. It had been running well, hadn't overheated, and nothing dropped off.

Next Steps

A few things to sort out before I go again (in a week's time). Obviously, the injectors is point 1. I've bought a full set of new ones from Emerald, largely because they are the best price I can find. I'll need to wire in new plugs but otherwise should be fairly simple. A new set of the ones I have would cost around 500 quid, and I don't think I want to risk used ones again now. Emerald can do a set for around 300. They're slightly smaller (320cc/min instead of 360), but that should still be plenty. I will have to rescale the map before running it.The trip into the middle of Norfolk to get the engine had been over some very bumpy roads, and it actually bounced the car out of the straps at one point! When I got it home I noticed a fuel leak, one of the unions on the fuel pump had come loose and was dripping, I presume because of all the bouncing. So tightening that up was the first job I did. Had to drop the undertray to get at it but simple enough.

Oil leaks from the rocker covers - I had used genuine AR gaskets, but these didn't cover the bit over the camshafts, which I'd been trying to seal with silicone, with little success. I searched again, and later model gaskets seem to be single piece rubber items which cover this area - so I've bought a new set which should hopefully solve the problem. More expense but since I'll have the plenum off anyway in order to fit the injectors, I may as well get it done while I'm in there and hopefully put the problem to bed for good.

I'm still not happy with the gearbox - again had awful trouble getting a gear, particularly reverse when the engine is running. I'm going to try fitting a larger clutch master cylinder, as I suspect that the clutch may just be dragging veeeeery slightly and making it hard to get a gear. Other people with s2000 gearboxes use a 0.7 bore cylinder, mine is 0.625, so that could be the problem. Again while the top of the engine is off it makes sense to change this and see.

So a lot to do before the return trip!

I need a Montage...

22nd October 2013

...lots of shots of me working in the garage late at night, emerging exhausted into the dawn, with welding torch in hand and a car all fixed and ready to go, a la "Rush"

Well, it wasn't quite that bad, though has been busy. The new injectors arrived. These are EV14, a different body style again, but still fit ok. There are long and short versions of EV14 however so you do need to check. Here they are compared to the EV1 originals (left) and EV6 volvo ones (middle):

I replaced the plugs on the loom and refitted. Everthing went into place with no trouble, with the exception of the injector clips. As a result, I had one which was not seated properly and leaked slightly on first start, but having pushed it home I've not had a problem since. I can't find any clips to fit so I'll keep an eye on things and maybe wire them in place if needs be.

The new rocker gaskets arrived, and I went to fit them, but alas, they didn't fit. It seems that the later engines must have had a groove machined into the mating faces for the gasket to fit into, but mine doesn't. So I had to resort to really carefully cleaning all of the gasket faces to make sure that there was absolutely no oil on them, before once again sealing it with silicone. This time it worked, so I guess that the on the previous 3 times I just hadn't cleaned the faces properly.

While the top was off of the engine I also changed the clutch master cylinder. I was worried that I might not be able to get it out without unbolting the pedal box, but actually there is just enough room. So an easy enough job. Then I could bolt everything back together...

That took me to the weekend, so I had a couple of days to test everything, in between rain storms. I rescaled the injection map in the ECU, and started her up. No problems there, all seemed fine. Next thing to test was my new clutch cylinder. Initial impressions were good, but obviously the only way to really be sure was to have a bit of a drive up and down our road. Happily, it seems to have cured the gearchange problem completely - it's now smooth and easy at all times. This was one of my main worries so I'm very pleased that it's fixed. In other good news, the oil leaks had stopped as well, and everything seemed to be working.

With it warmed up and on the drive, it seemed a shame not to give it a blip or two...

The next day I took it out again, (I just needed an excuse really.) But I thought that I may as well sort out the brake balance, since I didn't really want to start anything major. Basically a process of driving along, locking the brakes, then adjusting the balance bar until the fronts lock before the rears. It also beds the brakes in a bit, they got noticably better after a few goes. (Handbrake is still rather crap though, not sure if it'll be good enough). I'll need to lockwire the bar in place now it's set, but I have to buy a small drill first.

Annoyingly, the brake fluid resevoir cap is leaking - it's splashing out under braking. So a bit of cleaning up was required. I've tightened it as much as I can and hope that will solve it, but it doesn't seem terribly good really. A cap shouldn't need yanking up to FT to stop it leaking.

None of that could hide the fact that I now have a working car. Despite the snags, all of a sudden it feels like an entire car that just needs a few bits of work doing, rather than just a project sat in the garage. And it feels fun just being in it.

Rolling Road II - the Revenge

Come tuesday, it was time to collect the van, load up the car (in the dark and rain, again), and drive to Norfolk. Wednesday dawned and we were at Emerald for 9:45 for a 10am start. Into the cell again and the mapping began.

I was really nervous this time, stupid really, but I expected something to go wrong at any minute. But we got to lunchtime without incident, by which time the bulk of the map was filled in. He spent a lot of time on the bits where it'll actually spend most of its time - lower RPMs, pick up under load, all of those transient conditions which make the thing drivable. These are all done by holding the throttle at set positions and applying load to hold the engine at given RPMs, so that each combination of engine speed and throttle opening is mapped. At each point, he adjusts the fueling and ignition to produce the right mixture (read from a wideband lambda sensor) and the most power - and then backs it off just slightly to keep things safe.

Then after lunch, he started on the full throttle mapping. This was done differently, by doing repeated power runs from fast idle up to the limiter (6800rpm), then using the graphs produced to tweak things. I guess that holding things under full load and full throttle to adjust each point puts rather a lot of strain on things.

Here's an early run:

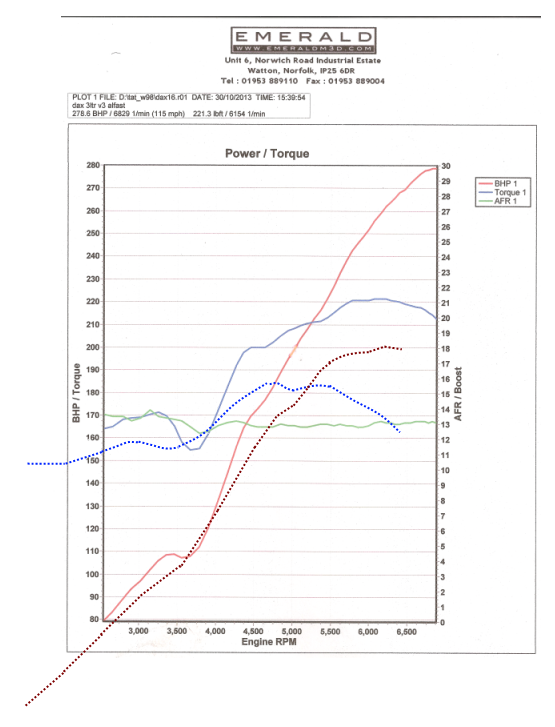

There were quite a number of these, each time tweaking a section of the map. As I watched each time and saw the power figures I got more and more pleased...to start with it was around 220bhp, then 270, then one touched 280, before settling to an average of 278-279. TWO HUNDRED AND EIGHTY! I'd tried to be realistic in my expectations, and so was going to be happy with anything over 250 - this is right at the top end of what I thought might be possible. Happy days!

The torque/power curves are shown below. I've also overlayed the curves from a 166 (the successor car to the 164, but still basically the same engine). My engine is shown as solid lines, the 166 as dotted.

As expected really, the torque curve has been extended upwards and rightwards - it rises faster, goes higher, and carries on rising for nearly 2000 rpm further. There are gains throughout, but the bulk of them are in the upper rpm range - exactly what you'd expect with a more aggresive cam and larger valves.

The interesting bit (well, to me) is that the "dip" which occurs at around 3500rpm, just before the engine comes "on cam", has been accentuated. It even dips slightly below the standard curve at one point, before going batshit mental and screaming off upwards. The mapper spent some time trying to reduce the dip but it's obviously a characteristic of the base engine, which has been made larger here. I'd guess at something to do with the length of the inlet pipes, or perhaps contamination between runners in the plenum chamber.

So that was all good. Even better, it totally aced the emissions tests, so I should have no trouble there. Cleaner than a Ford Fiesta apparently.

I noted a few other things during the test; the oil pressure gauge is now working, but seems not to be zeroing for some reason. The oil temperature sensor in the sump is clearly not doing anything, as it never got above 65 degrees all day, so I'll need to do something about that. I also found out that the fuel gauge is fine, I just hadn't read the instructions properly. It still needs callibrating but at least doesn't seem to be broken. I also callibrated the speedo, so it's overreading by 1mph which is about right. Unfortunately, I think the magnet came off during one of the power runs, as it stopped reading anything. I'll need to look at that and use some better glue.

So we were all done by 2o'clock. Had a bit of a chat with the man himself, Dave Walker, who's "Walker's workshop" column I've followed for years. Nice guy with a lifetime of engine knowledge and some great anecdotes. Then home, through one of the worst storms I've ever had the misfortune of driving through, and the associated mopping out when I got home. Apparently the bucket seats can hold a good few litres of water...

Once everything's dried out I'm really on the home stretch. I've got harnesses to fit, the driver's seat to bolt down properly, new indicators to replace the broken one, the dash to cover, a new speedo magnet to fit, an aeroscreen to fit and...that's about it, apart from the small matter of IVA.