I wonder what the weather will be like...Oh.

IVA

DAH - DUH - DAAAAAAAAAAAAAAH *thunderclaps*

7th January 2014

So the fateful day arrived. An early start as I needed to leave at 7am.

I had a quick breakfast and opened the door from the house to the garage. Right on cue, MASSIVE hailstorm. Hmmm, thanks, Universe. This quickly turned into mere heavy rain which I guess was an improvement.

I put on a ski jacket and sallopettes, helemet and ski gloves, got in, strapped in, and off I went. It doesn't start perfectly when the temperature gets down to 5 or so, because the cold starting has never been mapped in at those temperatures. But it does start after a couple of goes, with a pop and a bang or two.

It was a big moment turning out onto the main road for the first time. Not that I really had time to take it in, struggling with a misting visor, pouring rain and the general unfamiliarity of everything. Fortunately there was almost no other traffic about so I had a few minutes to do some hard stops, to check the brakes and see where the grip was, notice that the steering wheel was on at an angle (D'oh) and just check that everything was working properly.

I got to a petrol station after about 10 minutes and filled up. Turns out my jacket was waterproof but trousers weren't, but at least I wasn't cold. In fact, apart from the water seeping through from the seat, I felt completely insulated from the weather. Then the rain stopped so things were looking up.

The car as presented for IVA

The car as presented for IVA

I had 30 miles to go, about 20 of which was on dual carriageway. Traffic got heavier pretty quickly, which actually suited me as I was only going to go slowly on this first run, in the pitch dark, in wet conditions. So I pottered along with the rest of the traffic, tiptoe-ing around corners veeeeeeeery gently as I really had no idea of lateral grip on the semi-slick R888s. I found no unpleasant surprises though, though the car certainly does jump a bit if you hit standing water with them, as happened once.

I arrived just a couple of minutes late, and was waved into the shed by a couple of chaps in the requisit hi-vis vests. The car immediately drew a crowd of about 6 inspectors who were asking about it even before I'd got my helmet and gloves off! Obviously lots of them are into their classics and kits which has to bode well.

They offered me a brew (apparently not the case at all stations and not what I'd expected), then Dave the tester started straight away. Actually I had two testers, as they were short of appointments this early in the year, so another chap came along to help.

The whole thing had a very friendly, chatty air about it...not the Gestapo-style inquisition you might fear. The guys clearly saw their job as getting cars through the test, rather than finding reasons to fail them. Not to say they were going to overlook things, but the attitude was a positive one, not a "we want to catch you out" one. They went through the test, helpfully explaining each stage and what it was looking for, then said that I could have a go at sorting out any fails at the end, can't say fairer than that. They were also very positive about the general quality of the build, saying on a number of occasions things like "this is really nicely put together". And he thought that the ignition/fuel switches were "cool". So that made me happy :-)

The test took about 4 hours so was done by lunchtime. When the dust had settled, there were a few fail points:

- Noise: 99.2 and 99.3 dB, so 0.3 dB over the limit. That was a little annoying after I'd taken the trouble to test it at home, but anyway. It was a bit noisy on the motorway anyway really, even with a helmet on, so I won't be sad to make it a little quieter.

- Emisisons:This was odd. The emissions were way over, despite having been clean as a whistle on Emerald's rollers. They even let me switch to the special emissions map he'd done me, but that was over too. My current working hypothesis is that the baffles in the exhaust are affecting it somehow, so I suspect that this and noise will need to be solved together. I also made the elementary mistake of not having any documentation to prove the engine age, which made it subject to the most modern emissions limits...I must sort that out.

- Handbrake low effort:This didn't surprise me at all as I knew that the handbrake was crap, but it's not something you can test properly at home. 11.88%, needs to be 18%

- Front Indicators:If there was one which would make me cross, it would be this one. Although one of the testers thought that they were in a sensible place, they felt that the manual was vague enough that they should check with VOSA technical department, which they did. And after a long phone call, the word was that while side repeaters can be mounted on the arches and hence be "not fixed by design", front indicators can't be. As it stands, the requirement is very badly written and quite unhelpful. So I will end up putting smaller indicators in a less visible position in order to pass; ah well.

- Brake pushrods:There should be locknuts on the brake pushrods so that they can't rotate in use. I had wondered about this in fact, but they didn't come with any so I presumed that they were supposed to be floating.

- Projection:It passed all of the projection tests easily, with the exception of my headlight bracket, which the tester wanted a bit of trim around. No problem at all and I could have done it there and then.

The headlight alignment was out, of course, and he let me adjust it on the alignment machine. Interestingly the photons do have a "kicked up" beam pattern, but not the right way. Fortunately, the kick up is small enough that it counts as "flat" as far as the measurements go, so they do pass.

Other things which I had worried about, like self-centering, passed easily. People had been telling me that the steering wheel would never pass, but it did without problem. Others are convinced that cable ties to hold the wiring loom to the chassis is a no-no, but again, no problems. They did want to see under the boot, which would mean removing the undertray. I was prepared for this, and offered to remove a wheel (which is a much easier way of getting access). However they were really not keen on that (I'm guessing some health & safety thing about jacking a car up). Anyway, I had also brought a laptop with all of my hundreds of build photos on it, and they were happy just to look at those in the end.

So...a bit of work to do, but nothing too fundamental I don't think. Dave even gave me his card and mobile number in case I need advice on fixing any of the above, which I thought was extremely good of him.

Notes from the First Drive

The drive home was great though. It was daylight, the roads had (almost) dried out, and I felt a bit more confident about the car. Despite the fail, all of the unknowns, the will-it-works, the custom frankenstein engineering, all have come together to produce a car which works. When I look back and think of the hours I spent worrying about things like the throttle pully, would the narrower tyres be grippy enough, would the clutch work, would the small steering wheel be big enough, would the almost-rigid engine mounting cause too many vibrations etc etc, I realise that it's easy to forget how many things could have gone wrong, but didn't (yet!).

I still took it fairly easily and was able to take time to assess the car. Some things are still not quite working, the fuel gauge being one (I have a nasty idea it's working backwards), and the oil temperature gauge is better, but still not much use really. One thing which took me by surprise was the gearing - it's much lower than I'd expected (I've since found out that there's a secondary gear in the honda box which gears everything down). So it's doing about 3900 rpm in top at 80mph which is really too high - about the same as our 1.6 Mazda 3 does. Where I as expecting 6th to be a cruising gear on top of 5th, I've actually got 6 gears where most cars have 5. Not a problem in itself but it can certainly live with longer gearing; as it stands it'll top out at about 135. I might look towards fitting a diff with a longer gear in the future, largely to make long journeys more comfortable and economical. Maybe a project for next winter...

Other things have worked perfectly. The tacho position for example is a triumph, if I do say so myself. It was only afterwards that I realised I'd known what rpm I was at the whole drive home, without noticing that I was looking at it...it's just in the corner of your vision all the time, and you pick it up without specifically looking at it. The speedo is also well placed, as is the handbrake lever. Seats seemed confortable enough (but then I did have a great many layers of clothing on!), I didn't really notice them. Seating position is fine. Steering is fine even with the tiny wheel, a touch heavy when parking (although no worse than the MG with its massive great wheel, or indeed any car from the 80 without PAS), but lightens up as soon as you get going. The gearbox, well, the shift is everything I'd hoped for, an absolute joy to use. The engine also is everything I'd hoped it would be. Angry, raw, revvy, powerfull. Towards the end of the drive I did give it the full beans a couple of times and it really does go. I found it hard to compare to a normal car because it doesn't really feel much like a car at all. But going up through the gears at full throttle, I reckon that it blows through second and third in less than a second each...

The ride is much less crashy than my road car, despite having relatively tiny amounts of suspension travel, I'm guessing the higher profile tyres help here. It feels a bit "floaty" if anything at present over bumps, no doubt because the damping needs setting up. I can't really comment on handling yet as I was still fairly tiptoeing around corners, but it'll need a proper suspension setup anyway. It's certainly easy to drive though; the only time it becomes a little bit "idiosyncratic" is at low speeds, when it does tend to kangaroo a bit. Dropping down a gear tends to sort that though, so it's only really first gear stuff where you end up dipping the clutch a lot. For normal road driving it really seems very benign indeed.

When I came to the turning for home, I wanted to just carry on driving for another couple of hours...but alas, there's a little more work to do before that day comes.

Weight

They weigh the car on the rollers, and from that get figures for kerb weight (full of fluids & fuel, no driver), with one driver, and a calculated gross weight with two imagined fat blokes in it.

Kerb weight came out as 353Kg on the front axle, 275 on the rear. They left all of my tools in the boot when doing this, so I weighed them out when I got home - I had exactly 20Kg of stuff in the boot. So that gives me a kerb weight of 353 + 275 - 20 = 608 Kg; whilst not a 500Kg superlight, I'm very pleased with that considering the large engine fitment (A lot of car engined Rushes are in the 700 range) This gives a 56 - 44 weight split without driver, and 460bhp / ton.

With a driver and including the 20Kg of tools (Dave rather than myself, but it'll be close enough), we got 371 and 331Kg, for a total of 702. That improves the weight balance to 52-48.

There is a fair left-right imbalance with the driver in, which explains why the front left tyre locks up before the front right; again that should be sorted by a proper suspension setup and corner weighting session.

Making it all better

Handbrake

I did some research on the Wilwood callipers to find out what others had done. They certainly seem to cause a number of people problems with the handbrake. It also made me realise that while my reversing linkage increases the amount of cable pulled, this must also reduce the effective leverage I'm getting. I think I got confused!

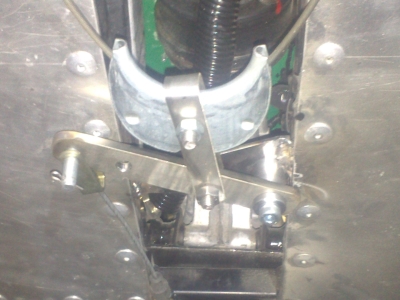

I eventually came across a mod made by Adithorp on Locostbuilders which involved putting a lever under the car to improve the leverage. This seemed like a good, simple idea, plus it would not require too much work.

I built my own version from a scrap piece of 6mm stainless bar which someone had given me "in case I could use it". Never thought I would to be honest, but a good stock of bits of metal seems to be a useful resource. I drilled holes for a pivot (12mm), the cable attachment to the rear (8mm), and two holes for the front cable - one to give 1:2 leverage and the other to give 1:3.

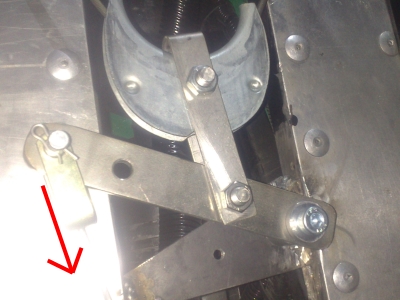

To attach this to the car, I welded a piece of 3mm plate between the chassis members. Upside down welding is rather hard and results in lots of drips, and a messy weld, so I had to tidy it up with some grinding. This was all complicated by being right next to the fuel line! I covered it in some sleeving and zip tied it up out of the way to give it some protection. The pivot is then made from some stainless bar, and finally I made a steel strip to join the u-shaped sierra cable holder to the new lever:.

Shown above before painting etc - the arrow shows the direction of pull. It's immediately much better - a quick test on our steep drive and the handbrake now holds with no problem, whereas before the car would just roll down. So hopefully that should be enough. I've set it to 3x leverage, though it would hold just as well on the 2x setting, just with a much harder pull on the lever. Hopefully that should be that one ticked off the list!

24th Jan 2013

Well I've been bashing on with things reasonably well, and have booked the retest for 12th Feb. I've got a week's snowboarding in between now and then though, so not actually that much time!

Post-drive Inspection

I had a good look at the wiring and bolts and things to see if anything had moved/rubbed. Nothing seemed to have come loose, which was reassuring. The brake fluid resevoir cap is crap though and still leaks. Not a hard thing to get right, you'd think, make a plastic screw top container which doesn't leak? Anyway I'll probably have to replace that at some point. A couple of wires in the engine bay looked like they might be rubbing or would rub, so I added a bit of sleeving here and there. Overall pretty tight though. And then I saw that, despite my care to test everything at full droop and compression, the nearside rear wheel had bitten the wheelarch:

Tyre shows the slight damage from rubbing the arch; arrow shows the point of contact.

Tyre shows the slight damage from rubbing the arch; arrow shows the point of contact.

It just shows that you really can't simulate all of the forces/range of movement sat in the garage. Anyway, nothing major, so I cut back the inside of the where it had rubbed.

One thing I was worried about was whether my undertray at the rear would cause masses of water and gunge to collect inside. But, despite the pretty bad weather it's been through, it was all surprisingly clean. The water clearly gets in there to an extent, but not like I'd feared it might.

Brake Cylinder Locknuts

Well this was easy (not often I get to say that!). Two 5/16" nuts, unscrew the pushrods, on with the nuts.

Noise

I've probably spent most time worrying about this. I'd really like a permanent reduction, but after a lot of reading, there doesn't seem to be a lot you can do in that regard short of remanufacturing the exhausts. So I've reverted to baffles; this time stuck WAY up the exhaust pipe (oooer). They have to be up inside because anything at the end will prevent the IVA man getting his emissions probe in (they only just managed it with the previous washer baffles), and that's a FAIL. So I've gone with the generic ones which everyone seems to sell:

There seems to be basically this design, or one which is a non-perforated tube and a cap stood off from the end, leaving a gap in the sides. There doesn't seem to be any information about which is best, or what effect either has on power or fueling, or anything really. So I think what I will do is use these for IVA, then remove them. I'll then cut them down/open them up as much as possible while staying under 99dB, and stick them in the end of the pipes for track days etc when I need to.

To get them in the straight bit of the exhaust, I needed to dismantle the silencers. These were riveted, so I had to drill them out, and weld nuts on the inside so that I can bolt them back together.

The silencer is a perforated 47mm pipe, wrapped in wire wool, and then some sort of wadding. It all looks quite well made, but because of the cat, the length of the silencer is pretty short, which I guess is the problem really.

In the last pic, you can just make out the baffle bolted into the perforated pipe.

Putting it all back together was a right pain in fact. The wadding all comes apart and the wire catches on everything and gets stuck in between the end of the tube and the pipe it has to go into and it's all just a bit of a mess. Not something I want to do too often.

Anyway, it still runs, which is good. It's definately muffled the sound considerably, I haven't tested it yet but I'm sure it'll be well below 99dB. It's also taken out the rawness and bark from the sound, so I don't think I'll leave it like that as that's half of the fun!

The question then is, how has it affected the fueling? Well I don't know yet, but I have a mobile engine tuning chap comming out next week so we will see.

12 February 2014

I had a bit of a play around with the baffles; they seemed to only take it down to about 100dB, so I chopped them up and tried a few different designs. In the end settling on a more open type which seemed to have just as much effect on the noise:

Still not quite enough though so I will need to keep my original ones in as well; hopefully (surely?) that will do it.

Indicators

Well this was a bit of an annoyance, stripping off the existing indicators (and all of the wiring), and fabricating up some stalks which attach to the suspension pick up point. Not too hard, just annoying. Anyway, they've turned out ok and will hopefully pass:

Epic Emissions Nightmare

Well the mobile man came out, with a small hand-held sensor which wasn't all that really. Especially after the probe melted in the exhaust (apparently, side pipes get much hotter than the end of a tin-top's exhaust). Anyway, despite me desperatly turning the fueling down, it was still waaaaay over. Much worse on the driver's side, where the CO was 3-4, instead of the 0.03 it should be. The other side was better, but still a bit over.

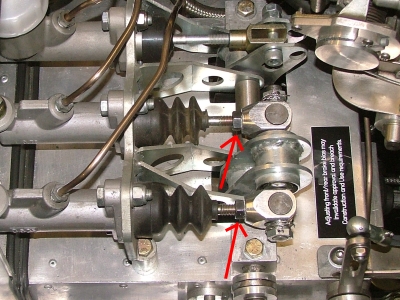

Couldn't really see what was wrong so we called it a day. During a good look later on, I noticed that the drivers side was actually misfiring horribly. What I'd taken as the sound of a lumpy idle because of the hotter cams, turned out to be a lumpy idle because it was only firing about a third of the time. It was only really obvious when compared with the other side:

Passenger side, idling normallyDriver's side, with missfire

So, I guessed that that was the cause of the emissions problem. But what was causing the missfire?

Well, cue a couple of weeks of despair and late nights, stripping it all down repeatedly (it would be the bank with the plenum on top, so getting at anything requires unbolting all of the inlet runners, some water pipes, throttle cable, and oil catcher).

I aimed at the simplest things first; so I tried new plugs; swapping the coilpacks from one bank to the other; swapping the injectors from one bank to the other; stripping and cleaning the fuel rail; all to no avail. I Checked for spark, and cranked with the inlet off so that I could see the injectors firing. I found a few things on the way which looked like they would be the cause (old plugs having a gap which was too small due to spark deposition, a couple of plug wells full of oil because the seals had shifted when the cover was tightened), but which turned out not to be.

I think that this has been the lowest point; to be so close to completion, and have the car apparently fighting me every step of the way, as if it's trying not to work, has been pretty depressing. Several nights I was tempted to just push it out into the rain and leave it there.I even had to postpone my IVA retest.

All of this left very little else to try; I took off the cam cover, AGAIN (a total PITA because it needs sealing with silicone, and being generally covered in oil needs careful cleaning or the sealant wont stick), to check the cam timing. Lo and behold, the timing was retarded. I have read about these early 24v engines slipping teeth on the timing belt, because of the very poor amount of wrap on the exhaust cam pully. (This was changed a couple of years after my engine, with a new tensioner and different belt path...if only I'd have known this at the begining!)

Anyway, I reset the timing (the 6th time now, I think), put it all back together, and started it. At least it did start, I was half expecting it to explode or something. And, finally, the driver's bank was running properly. Just as well as I really didn't have any ideas after that.

All is not totally well, as when up to temperature and running at about 3000 rpm, there is an occasional missfire; it just misses one beat every couple of seconds or so, just a slight stumble. So I think I will replace all of the coilpacks; at 20 years old they are probably not at their best. Expensive, but hopefully will sort this problem.

This all left me wondering when the timing slip can have happened; looking back through my videos, it's been sounding a bit rough at idle for as long as I can remember. But surely we'd have noticed it misfiring on the rolling road, especially when doing the emissions? I can only assume that there's been a combination of factors; perhaps the coilpacks were ok to start with but are now breaking down a bit, which, combined with the timing being out, has caused a progressively worse missfire?

Anyway, I will change the packs, then get the emissions tested at the local MOT place, and hopefully that will be that.

No wait, you're not quite done...

As I was running it, just after redoing the timing, it suddenly stopped. I quickly realised what had happened; one of the injectors had popped downwards and come unseated, causing petrol to rush out rather alarmingly. Fortunately the sudden drop in fuel pressure stalled the engine and the ECU thus shut off the fuel pump. Even so, there was rather too much petrol pooled all over the hot engine for my liking. Some rather frantic mopping-up ensued, fortunately without incident.

Now injectors are normally held into the rail with clips. However, I could not find any clips which suit the modern injectors I now have, and the old fuel rail. I was assured that the clips were only for ease of assembly and not needed, so I've been running without. Turns out they are needed, it seems. So I need to do something about that, I can't have that happening again. Having played around with lockwire I don't think that's going to be terribly effective, so I'm going to look to making up some spacers to go at the bottom of the injectors to prevent them from dropping down.

I swear it's actively fighting me now.

14th February 2014

Well, even that wasn't easy. Copper plumbing pipe turned out to be exactly the right size. So all I needed was to cut some 5mm rings out and slip them over the injectors.

But when you cut it, be it by hacksaw or pipe cutter, it leaves a burr inside which means that it's all too small. With such small bits of soft metal, they're impossible to clamp anywhere to file or ream...again a simple job turns out to be a hard one. I actually just gave up in disgust and went and had a beer instead.

In a slightly better/more constructive mood the next day, I turned up a mandrel and hollow drift. The drift hammers the rings over the mandrel, making them the right size and removing the burr:

Right. So make 6 of those, then I can refit the injectors. The rings slip over the end and simply prevent the injector moving up and down - down is the problem, they need to be kept pressed upwards into the fuel rail. With the spacers on they can only move a tiny bit so I shouldn't have a repeat fuel ejaculation.

Just waiting for the replacement coilpacks now and it can all go back together, again.

I don't wanna talk about it...

10th March 2014

Very briefly, tested emissions, the other bank was now way out, though the passenger bank is now just about ok on the special emissions map. Also was running like a dog; eventually traced to the driver's side inlet cam being about 20 degrees retarded, the passenger's about half that. Retimed and retensioned as the belt was now very loose. Was that me or is the tensioner shagged? Who knows, I'll just have to keep an eye on it, and have marked the cams and crank pully so that I can see if anything moves.

It now runs much, much smoother, and the "bark" is back when you rev it (so it wasn't the baffle which removed that, but the timing being out), but the idle is back to being very lumpy; like it was right back at the begining. So maybe that's right and the whole "misfire at idle" thing is a complete red herring? I will just have to cross my fingers at IVA and hopefully get it through with a bit of ecu tweaking if they'll let me. Not confident though.

On top of that, and after a week of late nights trying to sort out the timing, the driver's side cam cover cracked when I was bringing it up to temperature to check for leaks etc. I think I must have been overtightening it. Just what I need, 3 days before the retest. And yes, it's the one with all of the plenum and everything on top of it. Mind you I can now strip that all down in about 20 minutes after doing it all week. Which I am thoroughly sick of doing.

Tried fixing it lumiweld first, but couldn't get enough heat into the large casting with the blowtorch. Then I tried Araldite metal, but it still leaked after it had run for a bit. Then, a brainwave; I could try lumiweld again, with the casting over the gas cooker hob, and use the blowtorch on it. So I ground all of the araldite off with the dremel, "v"d the crack to give a nice big surface area for the lumiweld to flow into, and had a go.

This aproach certainly got it hot enough, although I could only easily get at the inside; for the outside I had to keep taking it off the hob and working on it for a minute or so before it cooled down. Unfortunately the pictures didn't come out, but I ended up with a reasonable-looking repair for a first attempt; if not neat, it looks and feels solid. Only one way to find out...

Retest 1

18th March 2014

Well, that was a bit of a disaster. At least my repair held and I got there, which is something I suppose. It didn't pass emissions even on the special map; and that map, retarding everything as it does, also makes it somewhat louder, so it hilariously recorded 105dB. Other bits were ok, except for the handbrake which was 14.5%; surprising as I thought that'd be fine, but still some way off it seems. Guess I need even more leverage.

On the emissions, since I now have proof of engine age, it's going to go through on the non-cat test, or 3.5% CO at idle, which should be easy. As it was, it was 3.6 (sigh), though I have seen it lower (down to 0.01 in fact) when playing around on the local garage's emissions machine. (Unfortunately I didn't save those settings due to unfamiliarity with the software, aka "user error"). No problems I said, I'll just plug in my laptop and tweak the fueling. "That's fine" said the tester, so I reached for my laptop. The laptop I'd left at home, charging merrily away. D'oh! It'd be funny if it didn't cost 90 quid.

So a little despondent. However the news that I only have to make the non-cat emissions did cheer me up somewhat, as I was getting a bit worried about hitting the BET levels. The way I read the IVA manual, I thought it would be the BET test, or then drop back to the test for the donor car (which is virtually the same). But the tester told me that when looking for an "exact match in the emissions database", it's on the kit car, not the car the engine came from. So I'd been interpreting it wrongly, though in my favour for once.

At least the weather was good this time. A fantastic sunny warm day in fact, so I had a good run with the car at least. It certainly attracts a lot of attention, though all good so far. It's shown up no unpleasant traits yet, aside from the low-speed kangaroo-ing, and is generally ludicrous, in the best way possible.

Back home, my time on the car is now more limited, because my kitchen looks like this:

Yes, it's the curse of DIY again. Worse, the garage is full of boxed up units ready to go in. Though I have (just) managed to fit the car in as well. So although I still have a fair bit I'd like to do (carpets, a good detailed clean to get rid of various paint splashes and bits of sealant overrun, some badges and bits to go on), I'm sticking to the purely essential.

One of those things is noise. I spent all of saturday on a DIY-pass out, playing with various baffles and things to try to get the noise down. I baselined it on the normal map, and it was up around 101dB on both sides; so had gone up from the 99.2 at the first test anyway. I guess I've messed up the packing with taking it apart several times. I tried various different baffle designs, inside the can and in the tailpipe. Eventually, with a db killer inside the can with the end welded shut, and a bung in the tailpipe with a long 20mm tube on it, and modifying the outlet so that it points somewhat downwards rather than straight out sideways, I got it down to 97.5dB. That should be comfortably in, but then I thought that the first time. Also, with a few revs the exhaust can is clearly leaking at the seams rather badly; it's obviously got far too much restriction in there.

So after several days of soul-searching, I came to the conclusion that the current silencers just aren't big enough; more than a third of each one is taken up with the cats, which as it turns out, I don't even need. So why not just get a new pair of silencers which run the full length of the can, instead of just 15-16 inches or so? Well, cost would be the main reason why not, but that aside, it did seem more and more logical. It can scarcely be more effort than dismantling them to fit bodged together baffles which I'll later need to remove. Also, I don't want to scrape through IVA only to be struggling with noise every time I go to a track day.

So that's what I've done. I had a chat with the fellow at Wunoff, who was very helpful indeed, and have ordered a new pair of silencers. I should be able to "just" cut the old ones off and these should slot straight in. Should be in the 96-98dB range he reckons, so with that, and maybe my "penny washer up the tailpipe" just for good measure, should be no problems. Apart from having spent all of my money of course, again.

Emissions I think should be easy enough, but I will check at the garage again and remember to save the map this time! The handbrake is a bit of an arse, I guess I'll just make an even longer leverage bar and try that.

Oh, and the final "turd in the waterpipe"; a second tester who was there on the day helpfully pointed out that two of my exhaust spring covers had fallen off (both front ones - heat and vibration I suppose - the rears are still solid). So I need to remake those, to rectify a fail on something I'd already passed on. Sigh. Better news next time, I hope.

3 Months Later...

16 June 2014

Well, the good news is, that it has finally PASSED! On the fourth attempt, which is rather embarrassing actually.

The car as it passed; not much visible difference apart from the indicators.

The car as it passed; not much visible difference apart from the indicators.

The reason I've not kept this diary up to date is frankly because the whole thing had got just too depressing to write about. Every change I made seemed to turn out to be wrong, or to mess something else up. The main bugbear in the end was the emissions. I came to the conclusion that the cams simply made it very dirty at idle, as no amount of ecu tweakage seemed to make enough difference. It also needed the Cats on to get the HC reading down; I couldn't get it through without them at all. Swinging the cam timing was what fixed it in the end; I spent rather a lot of money hiring a man with an emissions tester to stand there holding his probe while I made changes. In the end I found that advancing the passenger side exhaust cam by 2 degrees brought things into limits. There's still a difference between the banks but I could spend days messing around with it. It's further complicated by the fact that changing any one cam, even the exhaust, also affects the emissions from the opposite bank - must be crosstalk in the plenum chamber. So there are a lot of variables and I was happy just to get it in.

One happy side effect of all of this is that it does now idle and run at low revs much, much smoother than before - which makes it much better to drive in traffic as it's not kangaroo-ing nearly as much.

The handbrake also gave me jip, failing 3 times. The last one was particularly vexing as I'd had it tested at the local MOT station, where it passed...weird you might say. It turns out that VOSA (or DSVA, as they now are...it's taken so long that the government has rebranded them) use the "Design Weight" from your IVA appplication form when working out the required brake effort. This is effectively a made up figure, and I used the one quoted by Dax, which is 1010Kg. So despite the car weighing only 60% of that, it still has to have a handbrake strong enough for a 1000 kg car. I needed to fettle the lever and modify my cover to allow more travel on the handle. If I'd have known how they work it out, I'd have known the figure I was aiming for, but it's not very clear. Alternatively, if I'd have quoted the design weight as 900Kg, it would have passed on the second attempt. So the lesson is, quote the design weight as low as possible (it has to be more than the kerb weight plus 90Kg for each possible occupant). I do at least have a very good handbrake now though, pulling 290Kg on the rollers this morning which is something like 42% effort against the actual car weight...

I also did some work on non-exhaust noise...lined the bonnet and ally sides with Silentcoat which together adds about 3.5Kg, so not too bad. I also plumbed the idle valve into the main intake hose as the sucking noise was frankly offensive!

Oh and the clutch started to slip as it clearly wasn't up to the job. That really got me down. I imported an ACT clutch from the States which is rated for 370lb-ft of torque, against my 220, so will hopefully be ok. It's the one I wanted originally, but baulked at the cost. HAH! And even then Royal Fail managed not to deliver it, twice. Changing it took me 3 whole days and most of the evenings in a week, working to 11 or midnight; basically a complete strip back to rolling chassis, engine out, everything disconnected, the works. While I was in there, I took the time to move the sump-mounted oil temperature gauge to an inline adaptor in the oil hose from the block to the filter. The sump one was no use really, took ages to show anything at all and then never got much above 60-70. Inline it is much better.

So there we have it. The last 6 months have been pretty miserable really, it's felt like my own personal albatross. Which is a real shame as the rest of the build was (mostly) so enjoyable. But anyway, 6 years after I first ordered the kit, and 5 years after collecting it, I can say that the car is finally finished. Now to enjoy it!

I hereby declare this build diary...closed.