Brakes, Again, Again.

4th December 2011

Ah brakes, my nemesis it seems. I had a free day to spare in the garage over the weekend, so I planned to fill the brake system with fluid and bleed it. This I did, but it became rapidly clear that the system wasn't entirely fluid-tight. With each pump of the pedal I could hear ominous squirting noises.

The worst offender appeared to be the joint at the rear union - obviously, since it is the most innaccesible. However, several other joints were also leaking to various degrees. So I had to take off the rear tub, boot, undertray, transmission tunnel etc. A right bloody mess it was, brake fluid everywhere.

I tightened everthing up as much as I dared and tried again...but still it leaked. Eventually I had to accept that I was going to have to disconnect everything to see what was up. It wasn't immediately obvious what was wrong, so I went back to some of the original copper lines which came with the kit and compared them to mine. Then it became clear - the flare I'd made on my (kunifer) pipes didn't seem fat enough compared to the copper ones, and hence was not being pressed properly against the taper of the joint.

Copper flare supplied with the kit on the left - it's much fatter than the flare on the right.

Copper flare supplied with the kit on the left - it's much fatter than the flare on the right.

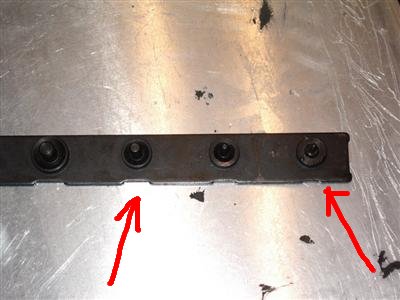

Close up of a bad (leaking) flare. It is sunk too far into the connector, so was not forced up against the taper of the other part of the connector properly.

Close up of a bad (leaking) flare. It is sunk too far into the connector, so was not forced up against the taper of the other part of the connector properly.

A further difference was in the type of connectors. The ones supplied with the kit had a much deeper taper sunk into them than the new silver ones I'd bought. As a consequence, there is more space inside the joint, so again a bigger flare is needed to fill it. The silver ones have a smaller void inside; the joins which hadn't leaked were all this type of connector.

Comparision of the two types of connector. The ones on the right came with the kit and have a much larger, deeper tapered well in the top; the one on the left I'd bought sepearately and has almost no taper inside.

Comparision of the two types of connector. The ones on the right came with the kit and have a much larger, deeper tapered well in the top; the one on the left I'd bought sepearately and has almost no taper inside.

So I set about trying to make the flares bigger. As mentioned, I've been using Kunifer/Cunifer (cupro-nickle) pipes, which are by all accounts better in every regard than copper. However, a few tests showed that it is far, far easier to make good flares in copper. I eventually managed to replicate the larger flares in the cunifer by leaving more of the pipe protruding from the flaring tool than was recommended. The tool I have has a guage against each pipe size to show how much pipe to leave protruding; after several trials I settled on using two sizes larger:

Right hand guage is the recommended one; I used the one on the left.

Right hand guage is the recommended one; I used the one on the left.

This produced flares similar to the copper ones. Much more full looking:

I cut the old flares from the two rear brake lines, and re-flared them - there was enough slack in the line to allow me the 10mm or so that this took. A test assembly of the rear lines and presurising of the system resulted in no leaks....result!

Unfortunately, some of the other lines didn't have enough slack in, so I ended up having to buy another role of brake line and redo most of the lines on the car. And in a final act of defiance, my flaring tool gave up the ghost when I had one more flare to do. The screw thread which compresses the pipe stripped completely. Fortunately a neighbour had one I could borrow.

Anyway, two weeks after the intial attempt, I was able to fill the system and bleed it all through...without leaks. The next day I checked each joint carefully for leaks - a couple were seeping so I tightened them up a touch. The next day...no leaks. I gave the brake pedal a good pumping and left it another day...no leaks. Then the same again, before I finally felt that it was safe to put all of the undertray and bodywork back on.

I'd been using a "1 man" bleeding kit, just a pipe with a one-way valve in it (easybleeds don't fit, apparently, because it's an odd-sized resevoir cap). This was enough to get the system primed, but isn't perfect. So I did a final bleed the old fashioned way, with the missus pumping the pedal and me twiddling the nipples, just to make sure there was absolutely no air in there.

In Conclusion...

- Well, it seems that cunifer flares differently to copper. It seems that you can get good flares if you put a greater length of pipe into the flare.

- It also seems that doing this may break your flaring tool.

- It is easier to get fluid-tight joints with copper pipe than cunifer, but cunifer is apparently a superior material with a longer life.

- The silver type of connectors are easier to get a good joint with than the brass Automec ones.

- If at all possible (and I don't think it is with a Rush build really), test the brake system as soon as you can, before you've built lots of stuff over and around it.

- Brakes lines are my least favourite thing.

In Addition...

I'd also had to get new flexi lines made to go to each calliper. The ones supplied with the kit have banjo fittings, willwood callipers require a female M10 fitting. So that was ok, but the new ones had different ends to join to the car. Rather than bolt on, these required a circlip (not supplied), nor could I find any in the correct size. So I had to make some up out of some thick wire, which fitted perfectly into the circlip grove and hold everything nice and tight. They work fine, but it took me hours of fiddling and faffing and I'd have rather just bolted 'em on.

I also fitted "belt-and-braces" trim where the flexi lines come through the aluminium side panel. Rubber trim around the hole, and a bit of split fuel hose over the hose itself to prevent any possible chaffing.

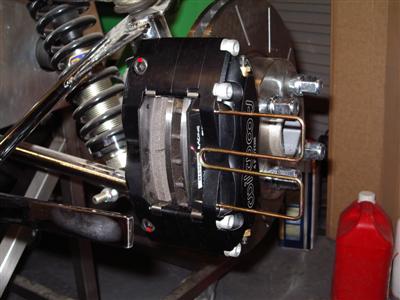

For brake pads, I'm using Ferrodo DS2500 ones - same as Pete F on his "no squeal" setup. They're also apparently very good performers. The one downside here is that they come to fit Willwood Powerlite (my rears) and Dynalite callipers, but not for Midlites (my fronts). However, the Dynalite ones will fit, it's just that the backplate needs a slot cutting in it, shown in the sequence below:

So, after all the pain, it looks as if I finally have a working set of stoppers. Next stop, wheels...