April 2015

Winter and Spring outings

Not too much to report from the early part of the year...I've had the car out a few times, whenever the weather allowed, which wasn't often! When the temperatures are cold, say < 10 degrees, it's very noticable that the grip from the tires is greatly reduced. My first trip out in feburary involved an unexpected sideways excursion at the first roundabout, despite taking things easily. Apparently it needs taking reeeeeeaaaaly easily in the cold. It's all bit on the twitchy side under power.

Aside from that, I also found that a Rush can be a very practical car. For example, it can (just) carry a paraglider and all associated gear:

OK so it was a bit cramped getting at the gearstick, but it did the job, and turned even more heads than usual...

Oil Cooler

As spring approached with its usual suddeness, I figured I needed to get a move on and start booking some trackdays. And before that, I needed to replace the oil cooler.

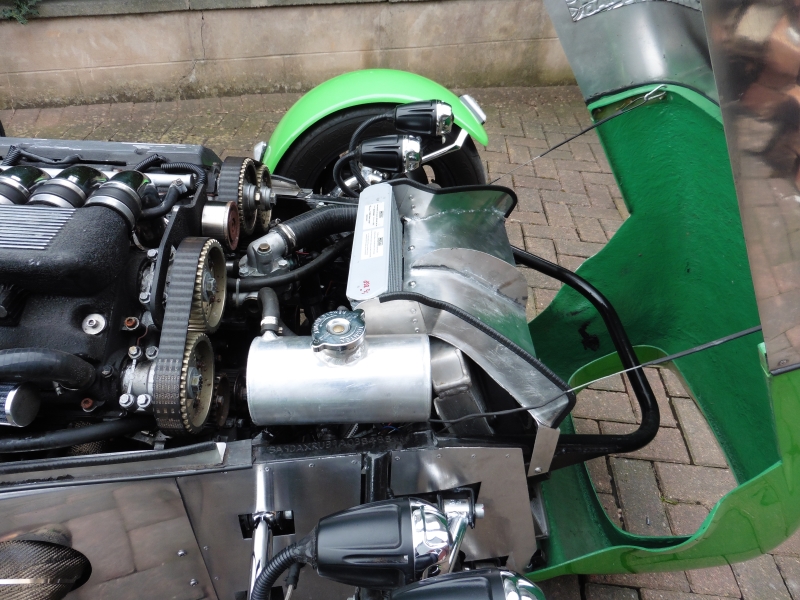

I'd been having a think over the winter and I still wasn't really happy that it was going to work well enough in its new position. I spent a lot of time thinking and experimenting, and eventually decided that the first thing to try was to add some ducting, to ensure that the maximum possible amount of air was going through the cooler. If I can't get enough air to it where it is, I'll need to do something more drastic - more holes in the nosecone, or try to move the radiator upwards and forwards and put a larger cooler in front of that. Either of those will be fairly major, so a bit of ducting is rather easier to try first.

I reckon that there are two problems with the cooler's current position; firstly, the bottom part is shrouded by the rad, and secondly, air can just go around it rather than through it. So I came up with a duct design which would hopefully address both of those problems.

It's just made of 1.2mm ally, mostly joined together with alumiweld, (which really is very good stuff, although there's a bit of a knack to it). That's apart from the center stiffening fin, because I ran out of alumiweld, so had to resort to araldite. I've kept the lip of the duct fairly high so as not to shroud the radiator; I could probably get a bit more through the cooler by extending it, but at the expense of what reaches the rad.

It's not quite as nicely made as I'd like, during the build I'd have done it again, but at this point I don't know if it's going to work or not, and time was a bit tight, so it'll do for now.

I also moved the cooler itself slightly, further back and tilted backwards, to give the airflow as wide a radius as possible. Will it work? Who knows...the track will tell.

Adventures in Noise

The other thing I had to sort out was the noise. My homemade baffles had got me by at Oulton, but they aren't really a great solution.

I had plenty of time over the winter to consider various possibilities, and eventually settled on the Decibel Devil. As with most things, there wasn't really any proper evidence as to what works and what doesn't, just odd posts here and there. So it was a bit of a gamble, as always

Anyway, they duely arrived, so I thought I'd do some tests to see what difference they made. I did the test like they do on track days, the noise meter 50cm from the exhaust opening, at 45 degrees. First, some tests with the open exhausts:

| 104.0 dB |

| 106.1 dB |

| 104.5 dB |

Two things were obvious here. Firstly, wrapping the headers has made the exhaust about 2 db louder than it was before, which isn't great. I'll see how the temperature goes and remove it if possible. Secondly, the 106 I think was an outlier, I blipped the throttle slightly and I think that pushed it up.

Then I put the Decibel Devils in and tried again:

| 101.2 dB |

| 101.2 dB |

| 102.3 dB |

Looks like a pretty solid 3dB reduction there, so the silencers do work, which is nice. I had the idea of adding a blanking plate to the end, to see if that made a further reduction, so I tack welded one together from some bits out of my metal box and tested again:

| 104.2 dB |

| 101.7 dB |

| 102.1 dB |

Interestingly, and surprisingly, it made little difference, perhaps even making things a bit worse. I did a couple of tests at 90 degrees (ie head on to the exhaust opening). I was getting a bit worried about annoying the neighbours so I only took a couple of readings.

| Head on, no plate | 101.3 dB |

| Head on, with plate | 100.0 dB |

So it may make a bit of difference directly in line with the exhaust, but may make it worse when off to the side. With that in mind, I decided not to bother with it for now. I thought it was also interesting that the reading taken head on with no plate was the same as it was at 45 degrees

So hopefully that will see me ok on track - first date is at Croft where they have a 105dB static limit; should be ok there I hope. I wasn't quite happy though, the curve of the exhaust meant that the silencers didn't fit without straining things; so I extended the support straps by welding on a couple of extensions:

First pic - as standard, Second pic - straps extended to sit better.

First pic - as standard, Second pic - straps extended to sit better.

A squirt of BBQ paint and all done. We'll see how that all works out at Croft...

Croft Trackday

The usual early trackday start saw temperatures of 1-2 degrees, though it was a glorious bright morning. I made my way to the circuit wearing thermals, pretty much all my clothes, and heavy ski gloves, and arrived just as things were starting to warm up. The usual briefing and sighting laps followed, then it was on to the circuit proper at 9:45.

It was still pretty cold and the rear was noticably lacking in grip at this point; so I felt my way around pretty carefully for the first few trips out. I stuck to 15 minutes or so out, then a cooldown lap, then 15 minutes resting. It took around half a lap each time before the tires and brakes started getting up to temperature.

As time went by I started to learn the corners, and the tarmac warmed up, and I could start leaning on it a bit more. A great circuit I thought, a real nice mix of corners, from twiddly technical bits, to "how brave are you feeling" fast swoopy bits. It also seemed like the car was moving around a lot more than at Oulton, or maybe I was just pushing things more.

A great group of people there too...had some great laps following an s2000 engined Elise, and a 600bhp Nissan GTR, then chatting it over in the paddock afterwards.

I am happy to report that my oil cooler and duct seemed to do the job admirably; the oil temp didn't get above 110 all day, so I was very happy with that. Another problem solved.

Unfortunately, my little C3 camera has decided to give up the ghost. It has been a bit sketchy for a few months, but this time it's stopped working for good. So I only got a bit of footage from the first couple of sessions in the morning. I was still feeling my way at this point so it's a bit pedestrian. But never mind, I'll be back for sure...

Bit disappointed in the camera really; I loved the design of it and I've used it for a few different things, on a helmet, on the car, but it's not much cop if it only works for a year. Time to try something different.

A day on a track leaves the car in a right mess...rubber streaks everywhere

A day on a track leaves the car in a right mess...rubber streaks everywhere

Noise, Revisited.

The car had been sounding rather loud all day; it got through the test at the track but was pretty close to the limit. Then coming home, it seemed ridiculous; but I was pretty frazzled after a day on track and I thought that the 2 hour trip back might have been playing with my brain.

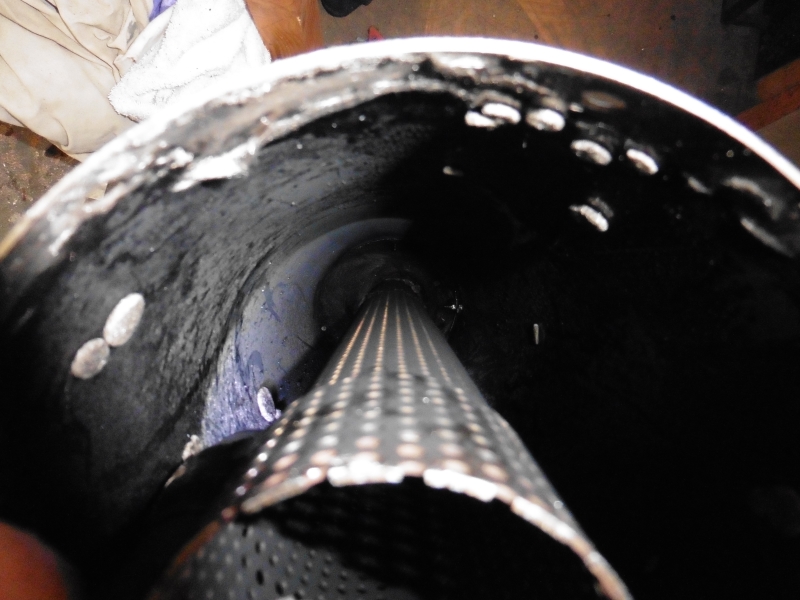

So come the weekend, I thought I'd remove the wrap from the headers and have a look at things. It always needs a good clean after a trackday and a bit of inspection is probably a good idea. It did still sound really loud though, so I took one of the exhaust cans off and had a look inside.

Ah. That's probably why it's sounding loud then. It seems that all of the glass wadding has melted into tiny pellets and presumably blown out of the end. Along with all but a tiny bit of the wire wool which was originally around the perforated tube.

Reading around the subject a bit, I'm going with the hypothesis that the exhaust wrap caused the silencers to get too hot (they were certainly much, much hotter than without it) and melt the padding. So hopefully removing the header wrap should help. In the meantime, I "just" need to repack the silencers before heading down to Stoneleigh show on saturday; I'm going to go with Acousta-fil which seems to get universally good ratings.

Stoneleigh

Packing the silencers turned out to be easy enough, and has certainly quietened things down somewhat!. The show was nice, if sadly getting smaller than it has been. However attendance from kitcar owners was still good so there was plenty to look at, and plenty of people to chat to. I went down on the saturday evening to stay nearby. It had been sunny (if somewhat chilly) all the way down the M6, unfortunately at around Birmingham, a great rainstorm positioned itself right in my path. Clear blue sky to the right and left, and torrential rain ahead. With not much choice I ploughed through it (I had my waterproofs on so not too bad from that point of view). In doing so I learnt something new about the car. A lot of water comes over the windscreen and covers the inside; so you need to keep wiping it by hand. You also get a lot of sympathetic looks from cars going by, their dry passengers waving at the stupid arse in the open top sports car, in this weather? You must be mad.

But, I'm happy to say that despite the thorough soaking, the car didn't miss a beat. I was pleased I'd wired everything with relays handling the high voltages so that all of the dash and column switches have very little load on them, given that it was all dripping wet. I'd of course polished and waxed it ready for the show, waste of time that was as it was filthy by the time I got there. Never mind, it's not a garage queen.

The rain held off for the show itself so all was good there. Alas, on the way home another, even more torrential, rainstorm hit me. It was one of those where the whole motorway slows down to about 30mph because it's so bad. I can only describe it as being like having a person sat on each front wheel arch with a hose pipe aimed at you. The fixed carpets took nearly 2 weeks to dry out properly!