July 2015

Speedo Sensor

The week before I was due to be at Oulton Park for a trackday (again), the speedo stopped working. Once again, the little magnet had come unstuck from the propshaft, as it had just before my final IVA test.

Obviously aralditing it on isn't working too well. However I can't really think of anything much better. However it's a right pain to get at and glue back on from underneath. So I figured that I'd move the sensor and magnet to the rear hub. This would have a couple of advantages; firstly, the hub turns at 1/3 of the speed of the propshaft (due to the 3.14:1 diff ratio), so there will be far less force on the magnet. Secondly, if it does come off, it will be about a million times easier to glue a new one on in that position.

It wasn't too hard; a bracket in 1.5mm stainless screwed & bonded onto the hub carrier to hold the sensor; and I extended the sensor wire to reach from the middle of the tunnel to the rear hub. The hardest bit was soldering the extension wires on under the car. I couldn't route the cable with the other electrics up the chassis rail without removing the tunnel (and hence the seats, dashboard, etc), so it went along the bottom rail and under the diff.

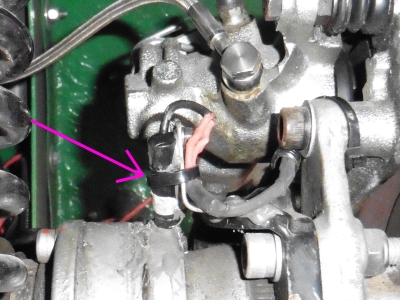

Pic below shows the sensor (pointing vertically downwards, arrowed) on its new bracket.

Happy to report that it seems fine; a quick tweak to the speedo callibration (divide it by 3.14) and everything is working again.

Oulton Park

Well, I finally made it to a track, second time lucky. I'd given the car a good look over the week before, checking all of the major bolts on the driveshafts, suspension etc and was happy to see nothing out of place. The red paint marks I'd put on all of the bolt heads are great for giving things a visual check over, I'd definately advise it to anyone building. Fluids topped up, tools in the boot, a spray bottle of windscreen cleaner and a sponge, camera mount sorted, and it was ready to go.

An early start at just past 6am in order to get there for 7:30 meant an easy run down the M6. Still pretty cold though even in midsummer, I had to wear gloves and everthing. Got there in good time to register, then hang around slightly nervously for 20 minutes while everyone who knew what they were doing was sat in the restaurant having breakfast. Purely because of the times I could make, this was a normal trackday, not a novice one, so most people, probably everyone else in fact, knew what they were doing. A lot turned up with their cars on trailers, all looking very professional, and there were a number of Time Attack teams there preparing for their event the next day. I felt a little amateurish sat there on me tod with a nutrigrain bar.

Anway, after the briefing, I got out for the "follow-my-leader" sighting laps as soon as I could. A very good idea this, as it quickly dispells the fear of the unknown. A few groups went out afterwards, then it was time. I was slightly nervous when the man asked for 5,000 rpm at the noise test but it passed, I was having flashbacks to IVA. And then it was out, on the track and hoping I wouldn't make a tit of myself.

I had a couple of indiscretions early on; outbraking myself (or more accurately, just not braking hard enough for some reason) coming into the Knickerbrook chicane and running onto the grass; and soon after completely missing the turn in for Druids and having a bit of a pant-filling moment. But nothing major and I built confidence as time wore on. A big boost came when I hitched onto the back of a group of Caterham racers. They were rather better at it than I was, but I had a power advantage which meant that I could keep up with them despite my poor cornering ability. It was really useful to follow their lines and see that actually, I can go around this corner 20mph faster than I had been. That was probably the biggest boost to my performance all day, so cheers fellas :)

Despite passing the static noise test, on about the 3rd session I got black flagged for triggering a drive-by noise sensor. Booo. Fortunately I'd bought my IVA baffles so I put them in and all was well...apart from the rattling noise, and I don't think they're great for power. Anyway I had no other problems so I'll see if I can do something better for next time.

The car itself is just a joy. Despite not having much setup done on it (corner weighted, geometry to specs but that's it) it handles beautifully. It seems to be obvious what it's going to do at all times. Bit too much power out of a corner? Oversteer but completely undramatic about it, just steer straight and carry on. Brake too late into a corner and lock up while turning in? A nice little drift as you come off the brake, again all very controlled. Push hard around that long sweeping bend? The outside front starts to wash out to tell you you're going too fast, no drama. I'm impressed. I'm sure it can be improved with a bit of tweaking, but it really is very good.

Coming into knickerbrook; round Druids (a corner I don't think I got right all day); and out of Lodge into Deer Leap.

Coming into knickerbrook; round Druids (a corner I don't think I got right all day); and out of Lodge into Deer Leap.

Below is a vid of the last session of the day, when I had more of a clue what I was doing. Still plenty of room for improvement mind.

For filming, I used an Innovv C3 which I'd just bought. The SJ4000 is fine, but had a couple of drawbacks - no external mic, and using a separate sound recorder is a pain; and it can't be charged on the go, and I'd kept running out of battery. I was looking at GoPro or Drift, but you're still looking at the thick end of 300 quid for the ones with the features I want - and I still don't like the GoPro form factor. The C3 is only £100, but it's big trick is that the camera lens is separate from the main unit, which also houses the mic.

Image stolen from Techmoan, who does the best video camera reviews I've seen, at http://www.techmoan.com/ Hope he doesn't mind...

Image stolen from Techmoan, who does the best video camera reviews I've seen, at http://www.techmoan.com/ Hope he doesn't mind...

So the camera unit goes in the footwell, where I can run a charging lead to it, and where it's out of the wind noise. The only real downside I've found is that, because the camera is cylindrical, and there's no live view, it's very hard to line it up level. Hence the video is on the tilt slightly. I'll need to measure it properly and mark it. Otherwise, I'm really impressed. I'm hoping that it'll work for snowboarding, as the battery can be inside my clothing and hence not exposed to the cold, which just kills batteries.

Back to the car...it coped pretty well with the constant thrashing - I was doing 15-20 minute stints, then coming in for 15 minutes rest. One issue I did notice were that the rear wheels were very hot indeed, hotter than the fronts. The brake balance certainly didn't seem to be biased to the rear though, and the handbrake isn't dragging so I'm not sure what that was about. And also, the oil temperature was very high, around 130 centigrade at times which is right on the absolute maximum, from what I've read. The oil cooler is not in a great position (behind the radiator) so maybe I need to look into moving it.

There were a few casualties though. Firstly, the backs of my hands got very sunburnt - didn't even think about that. Ooops. I lost an exhaust spring, somewhere, and a bolt came out one of the silencers. More annoyingly, my offside indicators stopped working on the very last lap of the day. Still, nothing major and it made it home with no trouble.

Indicators

A quick inspection a few days later quickly showed why the indicators had stopped working. The cable under the front arch had shifted and been flayed by the wheel:

My own fault. On the other side, the cable goes behind the silver stay. However on this side, there wasn't quite enough room for this and so I tucked it inside the stay, so that it wasn't visible from the outside. I thought that there'd be enough clearance to the tyre but obviously not.

Well, that'll learn me. Bit of a mess to tidy and resolder that lot, fortunately I'd left some slack in the wires so I didn't need to strip and replace the whole lot. Obviously I rerouted it over the stay, so that it's now (slightly) visible but hopefully safe from getting mangled again. The downside of the cool ultra-low-profile rush front arches is that there is very little room inside them for cabling, compared to something like a Westie or Caterham.

Autumn Mods

September 2015

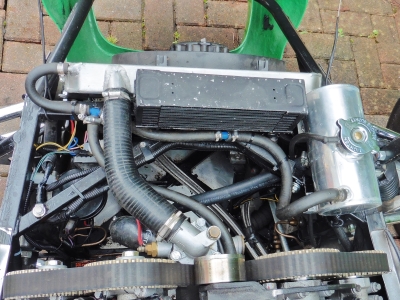

So the year slips by worryingly quickly. I thought I better get on with doing something about the oil temperature before winter sets in, as with the MGB taking up the garage, I have to do any work on the Dax outside.

The oil was getting too hot, so I figure that must mean that either the thermostat isn't opening and sending oil to the cooler, or the cooler isn't getting enough air to it. Since getting at any of the oil system gubbins is a right faff, I thought that I may as well just move the cooler anyway and see if it helps. Along with that I wanted to change the oil and filter, and fit a new battery as mine seems to have died, rather disappointingly. It won't hold a charge, even if completely disconnected it runs down in just a few days. I'd hoped it would last longer than that, but still.

I removed the cooler (which was full of oil, suggesting that the thermostat is at least opening sometimes) then spent some time working out where else it could go. I eventually decided that the only real place was above the radiator, which is where turbo'd cars often have the intercooler. It wouldn't go in front of the rad because of the fan, and there really isn't anywhere else. Moving it above the radiator would necessitate moving the water header tank, but nothing else too major.

To move the cooler, I had to weld a couple of small brackets on the top front chassis rail. Width-wise, space was at a premium, so I cut the cooler side mounting brackets off, and used metal epoxy to bond new brackets onto the bottom. Didn't fancy trying to weld or Lumiweld onto the thin ally. A slightly longer oil hose was needed, but I had enough left over from the build to reach.

Moving the water tank was a bit harder. Unfortunately, the bracket was on the wrong side; I really couldn't make it fit. I took a punt on a plastic VW one from ebay which looked like it might fit, but was actually miles too big. So in the end I resolved to cutting the bracket from the existing one, and Lumiwelding a new one on. It didn't turn out too badly in fact, the Lumiweld really is good stuff. Two new brackets welded onto the chassis rail, a longer bit of hose, and it was ready to go:

A lot more airspace behind it now, which should help. I may fit some ducting around the front to ensure air can't escape around it; some turbo'd cars even have extra ducts cut into the nosecone for the intercoolers so that could be an option if it proves necessary. Though I can't imagine that there won't be enough air going in through the nosecone, space for it to get out is more likely to be the problem.

I had also got thouroughly sick of the heat shielding under the driver's side exhaust. It makes getting at anything impossible without removing the side and headers, and makes that itself incredibly awkward. So I thought I'd try wrapping the headers instead.

Opinion seems divided on whether this is a good idea or a bad one, but as so often is the case, with few actual facts to go on, just opinions. I went with a titanium wrap rather than the cheaper GRP ones as they apparently don't hold moisture as grp can. I wrapped the header and also put some around the oil lines underneath it, just in case they were getting cooked by the radiant heat and that was the source of my sky high oil temperatures. Didn't get a good picture though :(.

Anyway, with it all back together, brought it up to temperature, and confirmed that the oil thermostat was working simply by feeling for when the cooler got hot, which it did, very suddenly, at around 85 degrees indicated oil temp. No leaks so I took it for a couple of runs.

Impossible to work it hard enough on the road to tell, but the oil temperature stayed at around 90. Only another track day will show for sure though. That was nice, what was less nice was to find that the oil cooler itself has a slight leak. Not a gusher, but enough to explain why there's always a patch of oil under the car. Annoying, I'll have to buy a new one at some point.

The exhaust wrap makes a noticable difference. Although it still gets darn hot around the header, clearly a great deal of heat is flowing away because the silencer, which I could rest my hand on after a normal run, is now scalding hot. Also, there's a lot more gas comming out on the overrun, with quite a noticable sound. Probably hasn't helped my noise problem any...still I will do the other side at some point so that at least everything matches.